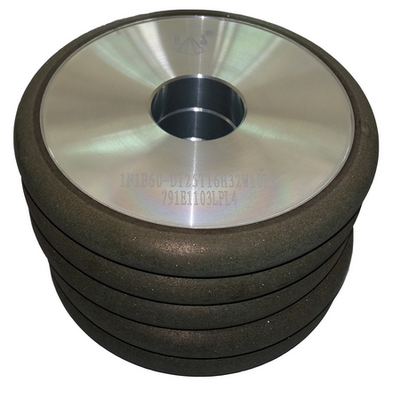

JJSTONE features: material selection performance excellent diamond or cubic boron nitride with imported high temperature resin with professional technology, mainly used in hard alloy tools, moulds, precision ceramic, PCD, PCBN, stone, magnets, semiconductor, glass, jewelry and other industries, drastically solved the difficult problem of customers, reduces the customer grinding cost, improve the machining precision and machining efficiency of the clients. All kinds of special specifications of products, we can be customized for the design.

How to order grinding wheel

1, Choose the right binder:

A,resin bonded grinding wheel : High bonding strength, elastic to a certain extent, poor heat resistance, coolant is not easy to enter. B,vitrified bonded grinding wheel: The porosity is high, the coolant is easy to enter, and the dressing is easy.

C,electroplated bonded grinding wheel: There are many sand grains and high teeth exposure, so grinding efficiency is high.

D,metal bonded grinding wheel: Sand high bond strength, very wear - resistant, difficult to repair.

2,Choose the right abrasive:

A,Dianmond:It is the abrasive with the highest hardness. However, during the processing of iron workpiece, due to the heat generated by grinding, iron and diamond will react and destroy the diamond, so it is not suitable for the processing of iron workpiece. B,CBN: Second only to diamond in hardness, suitable for grinding all kinds of steel above HRC40.

3,Choose the right abrasive grit size

4,Select the shape and size of the grinding wheel

Packaging & Shipping

Product packaging is generally cardboard box + pearl cotton + watt crate.

FAQ

We mainly customize grinding wheels according to customers' requirements, so please be sure to communicate with the sales staff before placing an order for grinding wheels.